Truck Trailer Parts

There’s no doubt about it, the winter season can be tough on your trailer. From the colder weather and harsher conditions, to the salty roads that can cause quicker mechanical erosion, wire wear, flat tires, ect. The season can cause a lot of damage and this check list can keep you hauling when spring time rolls around. Lets run through a quick checklist to keeping your trailer running smoothly before spring hits.

Brake Lights:

This is a good place to start as sometimes break lights can be the first thing to go when stored over long periods in the harsh Canadian climate. Just hook up the trailer and ensure that you have working tail lights, replacing any worn out bulbs.

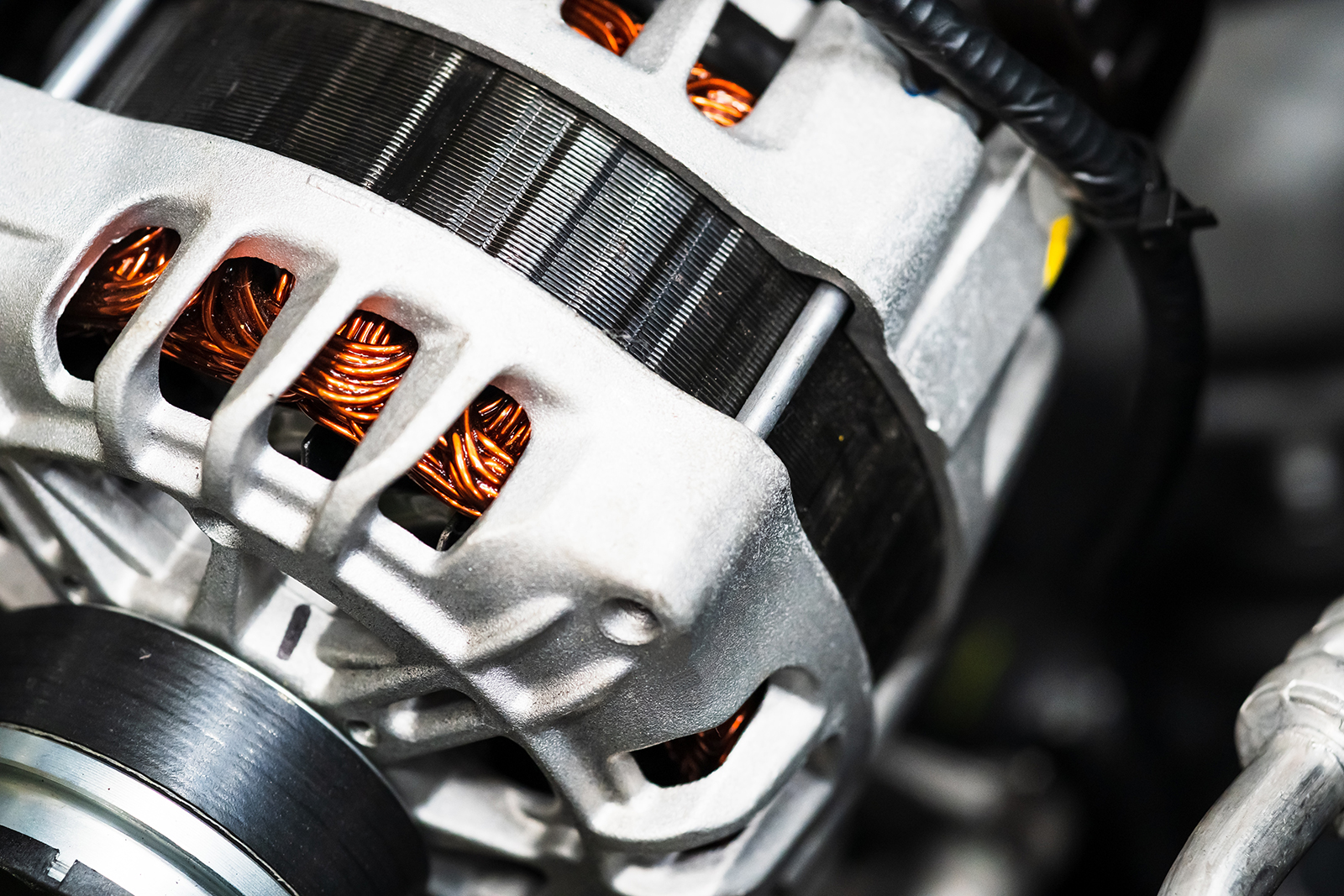

Trailer Wiring Products:

Sometimes if the lights aren’t working you may have a bad wiring connection from your trailer to your truck and testing them with a Om Voltage Meter is a good practice to keep. If you have already checked bulbs and fuses, you can check to see if the wires have any fray or loose strands sticking out of the shield. Most Trailer Connectors can be troubleshooted by eye and would have a problem that was viable by the naked eye.

Tire Pressure:

Under-inflation is the prime cause of tire problems, and an under-inflated trailer tire won’t sag like your car’s tires, because of its stiff sidewall construction. We recently pulled into a gas station with our 21′ boat and checked our pressure. Both tires looked perfectly normal, but our pressure gauge showed that one tire had only 15psi (instead of the rated 50psi), which would have quickly destroyed the tire. Don’t eyeball it! Check your tire pressure with a quality gauge.

Trailer Hitch:

A coupler is the metal piece that physically connects your trailer to the tow vehicle. Once the coupler is permanently bolted or welded to your trailer’s frame rail(s) at the front (this is the “tongue” area), it then fits over the round ball on the trailer hitch attached to your vehicle. Levers of various designs on the coupler clamp around the round ball tightly enough to prevent it from disconnecting, but they also allow just the right amount of play for proper pivoting around turns and over road undulations.

Couplers are subject to a large amount of wear-and-tear. They are called into action every single time you connect and disconnect your trailer from the tow vehicle. They move and bounce around on top of the trailer ball as you’re driving. If you leave your trailer outside, they are exposed to the elements. Eventually, the release mechanism becomes sticky, or the fit on the trailer ball becomes loose, or corrosion begins to take hold. Instead of replacing your entire trailer, which is expensive, the coupler is replaceable separately. It’s a cost-effective and convenient way to ensure that your trailer-to-hitch connection remains as secure as possible.

Trailer tongue shape determines the type of coupler you’ll need. Specifically, trailer tongues are known as “A-frame” when two frame rails join together at a 50 degree angle at the front (industry standard), “straight” when one single frame rail serves as an attachment point, or “gooseneck” when a trailer uses a round vertical post bolted underneath the front of the trailer. The coupler must also match the size trailer ball you’re using. If they don’t match, you might be better off replacing the coupler if it’s old.

If you are looking for any Trailer Parts give us a call at Pete’s Paint & Parts we have many Suppliers to find what you are after: